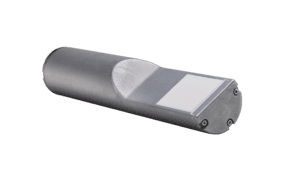

Aggregate Moisture Probe

Moisture sensors can measure moisture levels in materials being discharged from bins, on conveyor belts or within vibratory feeders.

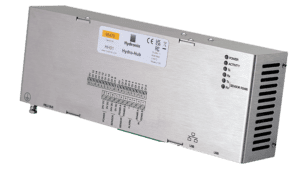

These measurements are then used by the plant control system in real-time to accurately proportion materials during weighing and/or control water addition during processing.

Typical Applications

Typical Materials

- Aggregates

- Sand

- Stones

- Other aggregates

Process Control

Related Products

Product Overview

CONTROLLING MOISTURE IN CONCRETE BATCHING

This video provides an overview of the Hydronix product range specifically designed for the concrete & construction industry.

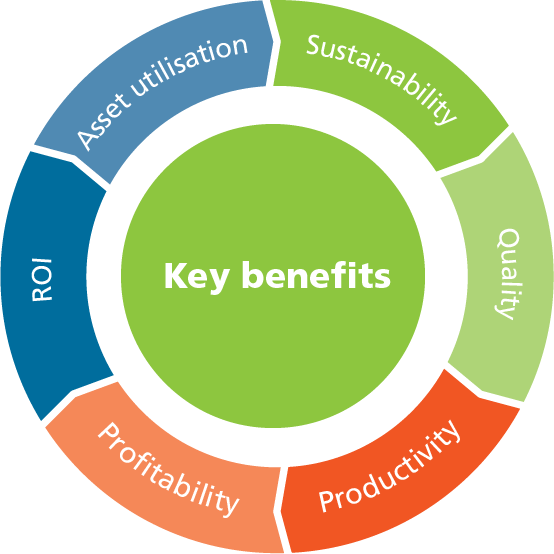

Key Benefits

Asset Utilisation

- Increase overall equipment effectiveness

- Reduce unplanned downtime

Sustainability

- Lower carbon footprint

- Save energy

Quality

- Less waste

- Consistent final products

Productivity

- Increase production yield through efficient use of material

- Online instant monitoring eliminates manual testing

Profitability

- Reduce waste and energy

- Automate processes

Return On Investment

- Average ROI in 3 months

- No need for expensive ongoing maintenance contracts

Related Videos

Resources

The addition of moisture probes and sensors to your plant processes allows for an optimised proportioning of materials during processing. Too much or too little moisture results in an inferior quality of product. With a Hydronix moisture probe for aggregates, you can always deliver consistency in your batching, weighing, mixing or storing of aggregates.

Our premium probes and sensors ensure you keep costs down and productivity maximised.

Discover how Hydronix is reshaping and enhancing moisture measurement for aggregates to improve the way the industry strives to become less wasteful and more productive.

Why an aggregate moisture probe is important

Without a moisture probe for aggregates, inconsistencies in production can become common, leading to a poor-quality product and additional expense. With real-time data, plant control systems can accurately use the information provided by the moisture probe and ensure materials are accurately proportioned during weighing and allow for the control of water addition throughout processing.

Positioned in bins and on conveyors, our moisture probes for aggregates allow for the readjustment of quantities throughout production processes ensuring the end result matches the high quality you have built your brand on.

Our robust aggregate moisture probes were originally constructed for use in concrete production but are now adopted across the construction industry for a host of processes within the trade. Able to measure moisture in aggregates, sand, stone and more, they can deliver accurate results instantly so you can always deliver premium quality.

Benefits of aggregate moisture sensor

Adding Hydronix moisture sensors for aggregates to your batching, mixing or storing of aggregates not only helps you to enhance your product and maintain its quality but also keeps your business as profitable as possible.

With less waste and a more consistent final product, you won’t have to spend additional funds on adjusting your processes to finesse your recipes and rectify past losses. Instead, you have consistency from start to finish.

With your plant equipment being utilised as it should, the functionality and effectiveness of the equipment is at its best, reducing unnecessary wear and potential downtime too. This results in a more sustainable process as you save energy and reduce your carbon footprint, reducing energy overheads.

Our moisture probes ensure total efficiency in the use of materials, and with online monitoring, remove the need for manual testing.

Types of aggregate moisture probe

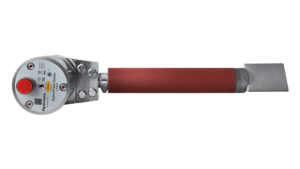

At Hydronix, we understand that at varying moments of the production process, moisture levels can vary. This variation leads to inconsistency. That is why we have aggregate moisture probes for each part of the concrete manufacturing process. The Hydro-mix moisture sensor is rugged and hard-wearing, primed for use on mixers or conveyors and able to measure at 25 times a second, rapid results are guaranteed. The Hydro-Probe is the moisture sensor probe that is simply installed into aggregate bins, and thanks to its shape, ensures optimal compaction of materials to guarantee accurate measurement. In addition, our orbiter probe allows for moisture detection in rotary pan mixers. With measurements calibrated to an accuracy of 0.2% for aggregates and 0.1% when in the mixer, your Hydronix probe maintains quality and delivers efficiency.

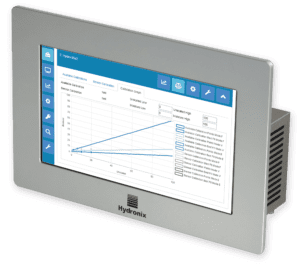

All of this is easily, and seamlessly connected to our Hydro View touchscreen system that allows data to be viewed and sensors managed as they are in action.

With simple installation and rapid results, Hydronix aggregate sensors are the only choice for accurate aggregate moisture content calculation, ensuring your end product is made exactly to your specifications.